TiO2 is a versatile and widely used material with applications in various fields, including photocatalysis [1], solar energy conversion [2], gas sensing [3], battery [4], and cancer therapy [5]. However, TiO2 has certain limitations, such as a wide bandgap and low visible light absorption, which restrict its efficiency in some applications [6].

Carbon (C) doping enhances TiO2 performance by modifying its electronic structure, improving visible light absorption, reducing the bandgap, and promoting charge carrier separation [7], [8], [9], [10], [11], [12]. It introduces defects and oxygen vacancies, enhancing charge separation and reducing recombination [13]. C doping also increases TiO2 surface area and porosity, improving reactant adsorption and overall photocatalytic performance [14]. These properties can be optimized by varying carbon content, doping methods, and synthesis conditions [15]. Carbon is inexpensive and abundant, making C-doped TiO2 a cost-effective photocatalyst with scalable synthesis methods [16]. It exhibits good stability and durability, with enhanced thermal stability and resistance to photocorrosion, extending its lifespan and maintaining photocatalytic activity over multiple cycles [17]. These attributes make it ideal for water and air purification, energy production, and environmental remediation [18]. C-doped TiO2 NPs are particularly promising due to their high surface area, enhanced photocatalytic activity, tunable properties, facile synthesis, and versatility [19], [20], [21], [22].

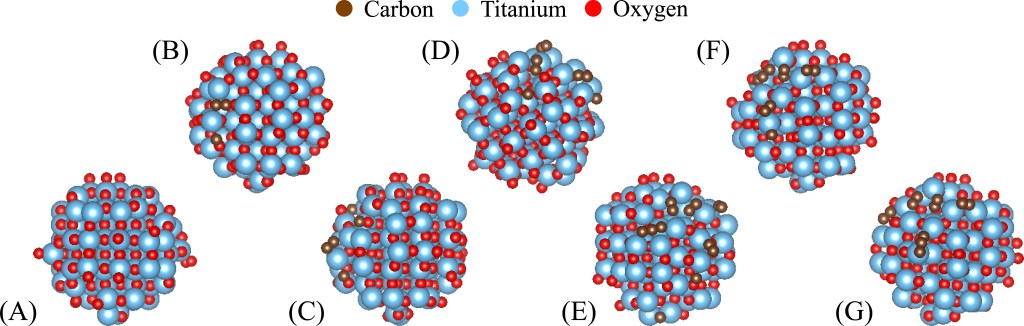

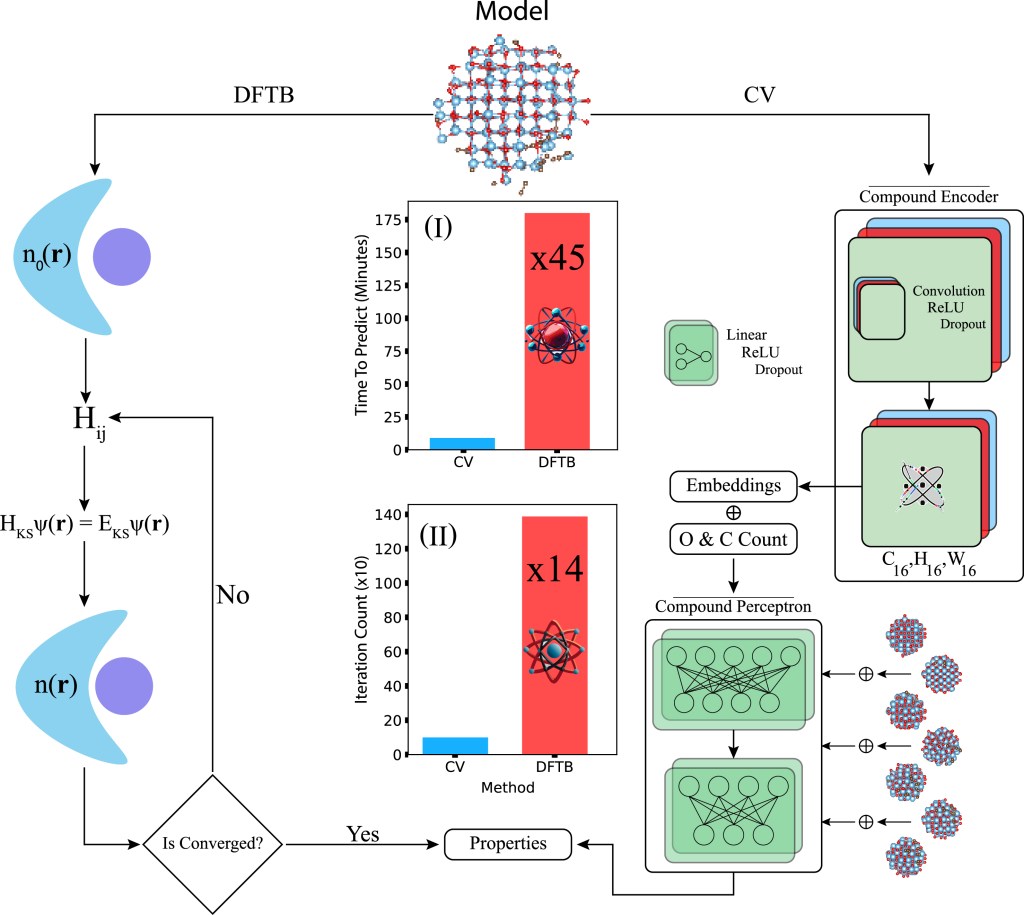

In this study, an innovative approach is explored that combines Density Functional Tight Binding (DFTB) with Computer Vision (CV) techniques to analyze the electronic structure and enhance the photocatalytic capabilities of Carbon-doped titanium oxide nanoparticles (C-doped TiO2 NPs). The findings reveal that carbon doping, in levels ranging from 0.1% to 0.6% progressively alters the material’s electronic structure and photocatalytic activity. Specifically, the energy gap decreases significantly from 3.160 eV for undoped TiO2 to 0.565 eV at 0.6% doping, with no substantial changes observed beyond 0.6% doping.

A notable correlation between increased carbon doping and a rise in total energy suggests a complex interaction between carbon incorporation and the energetic as well as structural dynamics of TiO2 NPs. This interaction could enhance photocatalytic efficiency, especially under visible light, by reducing the band gap through carbon doping. The use of CV methodologies improves computational efficiency and predictive accuracy. These techniques validate the DFTB results and accelerate the material discovery process via machine learning models. The ability of CV methods to accurately predict the properties of C-doped TiO2 NPs across various doping levels, combined with their computational advantages, represents a significant advancement in materials science.

Cite this article (BibTeX):

@article{KURBAN2024113248,

title = {Enhancing the electronic properties of TiO2 nanoparticles through carbon doping: An integrated DFTB and computer vision approach},

journal = {Computational Materials Science},

volume = {244},

pages = {113248},

year = {2024},

issn = {0927-0256},

doi = {https://doi.org/10.1016/j.commatsci.2024.113248},

url = {https://www.sciencedirect.com/science/article/pii/S0927025624004695},

author = {Mustafa Kurban and Can Polat and Erchin Serpedin and Hasan Kurban},

keywords = {C-doped TiO, DFTB, Computer vision, Electronic properties, Photocatalysis}

}References

[1] Schneider, J., Matsuoka, M., Takeuchi, M., Zhang, J., Horiuchi, Y., Anpo, M., & Bahnemann, D. W. (2014). Understanding TiO2 photocatalysis: mechanisms and materials. Chemical reviews, 114(19), 9919-9986.

[2] Liao, L., Wang, M., Li, Z., Wang, X., & Zhou, W. (2023). Recent advances in black TiO2 nanomaterials for solar energy conversion. Nanomaterials, 13(3), 468.

[3] Yan, Z., Zhang, Y., Kang, W., Deng, N., Pan, Y., Sun, W., … & Kang, X. (2022). TiO2 gas sensors combining experimental and DFT calculations: a review. Nanomaterials, 12(20), 3611.

[4] Chen, W., Wei, L., Lin, Z., Liu, Q., Chen, Y., Lin, Y., & Huang, Z. (2017). Hierarchical flower-like NiCo 2 O 4@ TiO 2 hetero-nanosheets as anodes for lithium ion batteries. RSC Advances, 7(75), 47602-47613.

[5] Sugiono, F. A. F., & Risanti, D. D. (2019). Tunable surface plasmon resonances of Au@ TiO2 core-shell nanoparticles on the dssc (dye sensitized solar cells) performance. Indonesian Journal of Materials Science, 20(3), 106-110.

[6] Almaie, S., Vatanpour, V., Rasoulifard, M. H., & Koyuncu, I. (2022). Volatile organic compounds (VOCs) removal by photocatalysts: A review. Chemosphere, 306, 135655.

[7] Ghumro, S. S., Lal, B., & Pirzada, T. (2022). Visible-light-driven carbon-doped TiO2-based nanocatalysts for enhanced activity toward microbes and removal of dye. ACS omega, 7(5), 4333-4341.

[8] Wu, G., Nishikawa, T., Ohtani, B., & Chen, A. (2007). Synthesis and characterization of carbon-doped TiO2 nanostructures with enhanced visible light response. Chemistry of Materials, 19(18), 4530-4537.

[9] Yang, Y., Ni, D., Yao, Y., Zhong, Y., Ma, Y., & Yao, J. (2015). High photocatalytic activity of carbon doped TiO 2 prepared by fast combustion of organic capping ligands. Rsc Advances, 5(113), 93635-93643.

[10] Hua, L., Yin, Z., & Cao, S. (2020). Recent advances in synthesis and applications of carbon-doped TiO2 nanomaterials. Catalysts, 10(12), 1431.

[11] Eitel, D., Graml, J., Hoppe, J., Kaliwoda, M., Hornfeck, M., & Helbig, U. (2023). Synthesis and Structure of Carbon‐doped TiO2 by Carbothermal Treatment. Nano Select, 4(7), 454-461.

[12] Heffner, H., Faccio, R., & López–Corral, I. (2021). C–doped TiO2 (B): A density functional theory characterization. Applied Surface Science, 551, 149479.

[13] Guan, S., Cheng, Y., Hao, L., Yoshida, H., Tarashima, C., Zhan, T., … & Lu, Y. (2023). Oxygen vacancies induced band gap narrowing for efficient visible-light response in carbon-doped TiO2. Scientific reports, 13(1), 14105.

[14] Shi, J. W., Wang, Z., He, C., Li, G., & Niu, C. (2015). Carbon-doped titania flakes with an octahedral bipyramid skeleton structure for the visible-light photocatalytic mineralization of ciprofloxacin. RSC advances, 5(119), 98361-98365.

[15] Shim, J., Seo, Y. S., Oh, B. T., & Cho, M. (2016). Microbial inactivation kinetics and mechanisms of carbon-doped TiO2 (C-TiO2) under visible light. Journal of hazardous materials, 306, 133-139.

[16] Park, Y., Kim, W., Park, H., Tachikawa, T., Majima, T., & Choi, W. (2009). Carbon-doped TiO2 photocatalyst synthesized without using an external carbon precursor and the visible light activity. Applied Catalysis B: Environmental, 91(1-2), 355-361.

[17] Yan, X., Xing, Z., Cao, Y., Hu, M., Li, Z., Wu, X., … & Zhou, W. (2017). In-situ CNS-tridoped single crystal black TiO2 nanosheets with exposed {001} facets as efficient visible-light-driven photocatalysts. Applied Catalysis B: Environmental, 219, 572-579.

[18] Ariza-Tarazona, M. C., Villarreal-Chiu, J. F., Hernández-López, J. M., De la Rosa, J. R., Barbieri, V., Siligardi, C., & Cedillo-González, E. I. (2020). Microplastic pollution reduction by a carbon and nitrogen-doped TiO2: effect of pH and temperature in the photocatalytic degradation process. Journal of hazardous materials, 395, 122632.

[19] Negi, C., Kandwal, P., Rawat, J., Sharma, M., Sharma, H., Dalapati, G., & Dwivedi, C. (2021). Carbon-doped titanium dioxide nanoparticles for visible light driven photocatalytic activity. Applied Surface Science, 554, 149553.

[20] Negi, C., Sharma, H., Kandwal, P., Singhal, R., & Dwivedi, C. (2020). Carbon-doped titanium dioxide nanoparticles: A facile synthesis, characterization and their photocatalytic activity. Materials Today: Proceedings, 28, 710-712.

[21] Habibi, S., & Jamshidi, M. (2020). Sol–gel synthesis of carbon-doped TiO2 nanoparticles based on microcrystalline cellulose for efficient photocatalytic degradation of methylene blue under visible light. Environmental technology.

[22] Hua, L., Yin, Z., & Cao, S. (2020). Recent advances in synthesis and applications of carbon-doped TiO2 nanomaterials. Catalysts, 10(12), 1431.

DOI

DOI Code

Code Data

Data